With the increasing popularity of electric vehicles (EVs), the demand for EV charger is also growing. However, charging modules may experience some faults and damage after long-term use. In this regard, how should users judge and respond? Professionals believe that charging modules generally encounter six common faults during use, which are module protection, module failure, uneven current sharing, communication interruption, half-load output, and failure to reach the set output voltage. Therefore, diagnosing faults of charging piles can be carried out in the following steps:

Visual Inspection

Check if the power cord is damaged or loose, and ensure the socket and operating voltage are normal. If the power issue cannot be resolved, it may be necessary to replace the power cord or socket.

Check if the charging interface is blocked by foreign objects, which could cause poor contact. Clean the interface and ensure a secure connection. If the problem persists, the charging interface may need to be replaced.

Check if the communication between the EV charger and the electric vehicle (EV) is normal. This issue may arise due to damaged cables, loose connectors, or incompatible communication protocols. Repair the damaged cables or loose connectors, or upgrade the EV charger software to be compatible with different vehicle models.

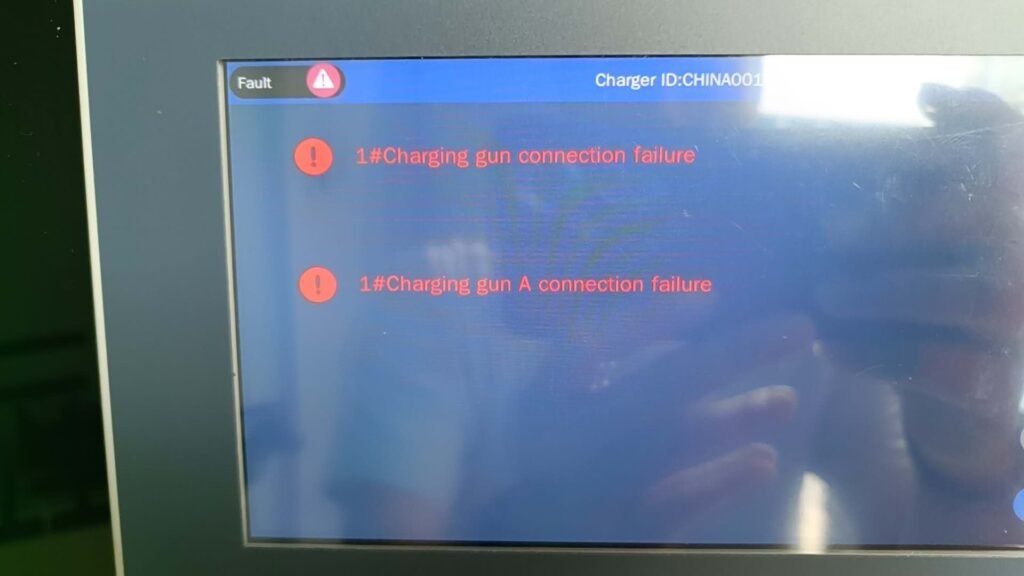

Alarm Analysis

Most modern EV charger are equipped with an intelligent alarm system, which automatically triggers an alarm when an abnormality is detected. For example:

- Overvoltage, undervoltage, or overtemperature in the AC input of the charging module will trigger the charging module’s protection mechanism. Please confirm the issue based on the fault code.

- A charging cabinet with a glass door or poor airtightness may cause the charging module to activate overtemperature protection.

- Excessively high ambient temperature in the equipment room will also lead to the activation of the charging module’s overtemperature protection.

Controller Inspection

The controller of an EV charger is its “brain,” responsible for coordinating and managing the entire charging process. Many controllers are equipped with a self-test function, allowing the self-test program to be run by connecting to a computer and using dedicated software. If the controller malfunctions, it may be necessary to replace it with a new one.

Parameter Detection

To identify issues such as short circuits, open circuits, overcurrent, or undervoltage in the circuit, professional personnel are required to conduct electrical parameter detection. Specifically, it is necessary to use professional electrical testing tools such as voltmeters and ammeters to measure key electrical parameters of the EV charger, including input/output voltage and current. Compare the measured results with the values specified in the equipment specification sheet or within the normal operating range—any significant deviation may be a sign of an electrical fault.

Spare Part Replacement

For faults that are difficult to identify through other methods, the spare part replacement method can be used. By replacing potentially faulty components one by one (such as power modules, communication boards, etc.) and observing whether the fault disappears, the scope of the fault can be narrowed down and the root cause can eventually be identified. This method is particularly suitable for handling complex or intermittent faults.

Connection Verification

Poor or interrupted connections are often common causes of charging failure. Ensuring a secure and reliable connection between the EV charger, the power grid, and the user’s vehicle is a crucial step in preventing charging faults. Check whether the power plug, the vehicle’s charging port, and the cable connections between them are tight and free of looseness. At the same time, confirm that the power supply is stable and meets the equipment requirements.

Fault Codes

EV charger are usually equipped with a fault code manual or online support resources, which detail various fault codes as well as their corresponding fault types and solutions. When a specific code appears on the chargier’s display screen, operation and maintenance personnel should quickly refer to the manual and conduct fault diagnosis and repair in accordance with the provided guidelines.

Summary

It is inevitable for EV charger to develop some faults after long-term use. Conducting maintenance in a timely manner and addressing EV charger faults promptly can ensure smoother charging for electric vehicles. During the maintenance of EV charger, in addition to the methods mentioned above, you can also clean and maintain the EV charger regularly and inspect the EV charger periodically to ensure their normal operation. If you encounter any EV charger fault issues and need assistance, please contact us.