Amplifiers, Supporting 20kW Power Module Current Detection

The "Duet" of OPA2171 and AMC1200B

“Analog signals never lie—you just need to understand their language.”

In a DC charging module, accurate current sampling is not only crucial to control precision, but also directly impacts the safety and stability of the entire system. And the combination of OPA2171 and AMC1200B is what makes all this possible.

Background of the Power Supply Module: Current Detection is the First Step in Control

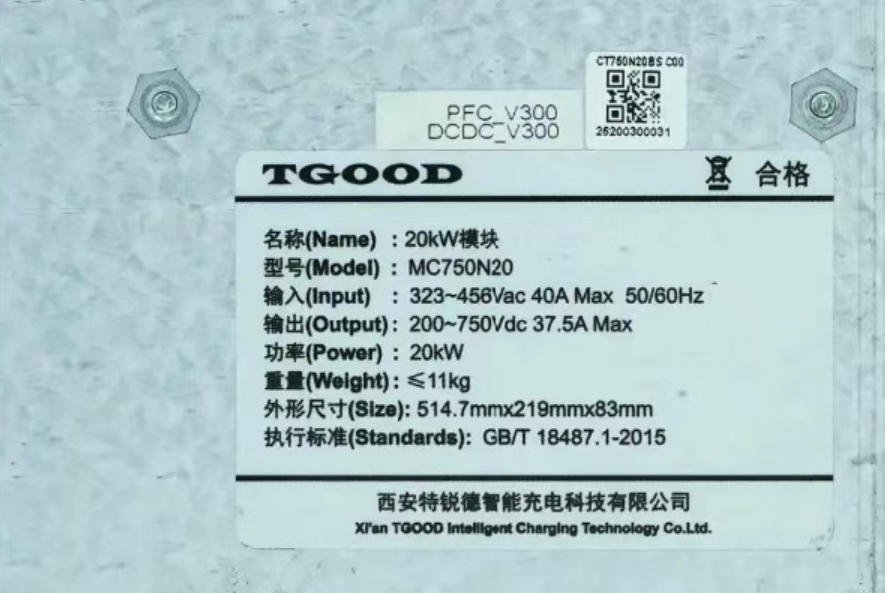

In a 20kW-class three-phase DC charging pile module such as the TGOOD MC750K20, the current sampling circuit is mainly responsible for two tasks:

- Accurately detect three-phase PFC current to ensure power factor control and energy efficiency conversion;

- Provide high-voltage isolation for the signal path to prevent high-voltage side interference from affecting the low-voltage main control unit (MCU).

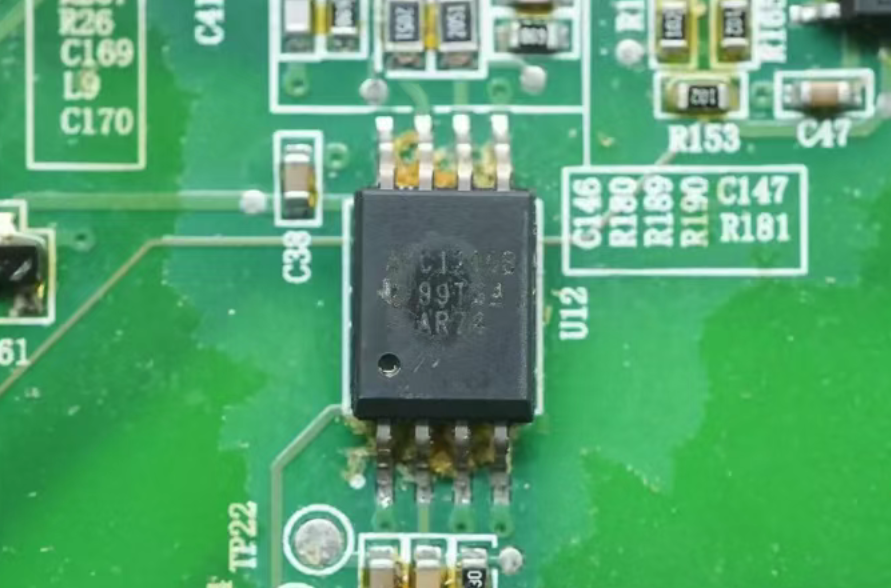

The isolation chip used for current sampling is from Texas Instruments (TI), with the model number AMC1200B. It is a high-precision isolation amplifier and adopts the SOIC8 package.

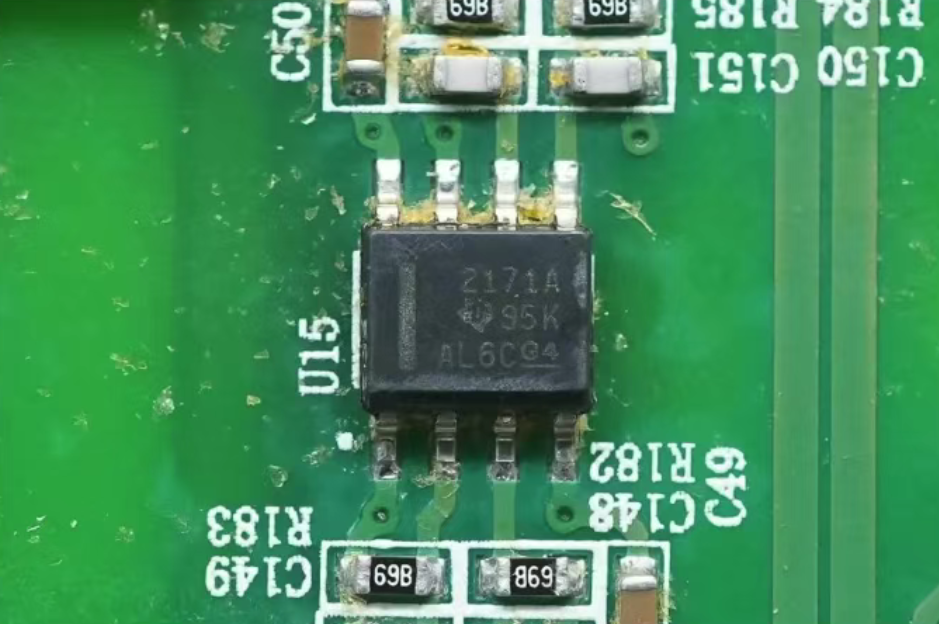

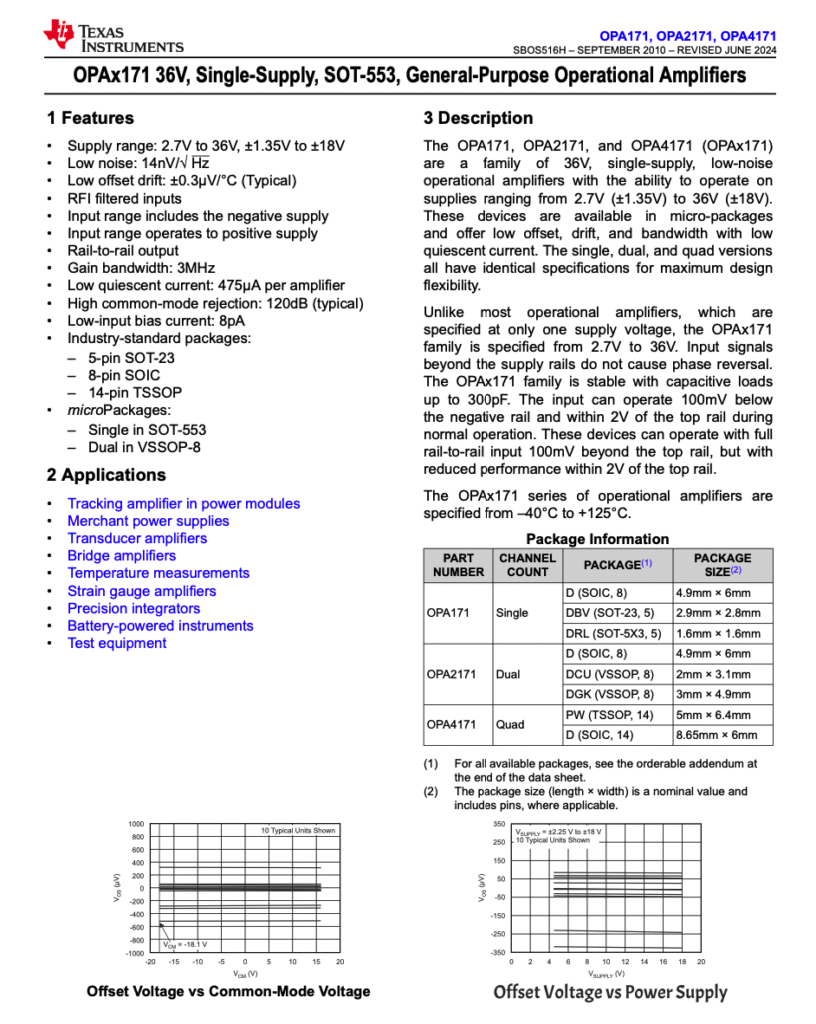

The dual operational amplifier (dual op-amp) is from Texas Instruments (TI), with the model number OPA2171. It is a single-supply general-purpose amplifier, used for current signal amplification, and adopts the SOIC8 package.

- 4 units of OPA2171: Serve as pre-stage current amplifiers;

- 3 units of AMC1200B: Used for isolation detection and differential output of PFC in each phase.

OPA2171: The Foundation for Stable, Accurate, and Efficient Current Amplification

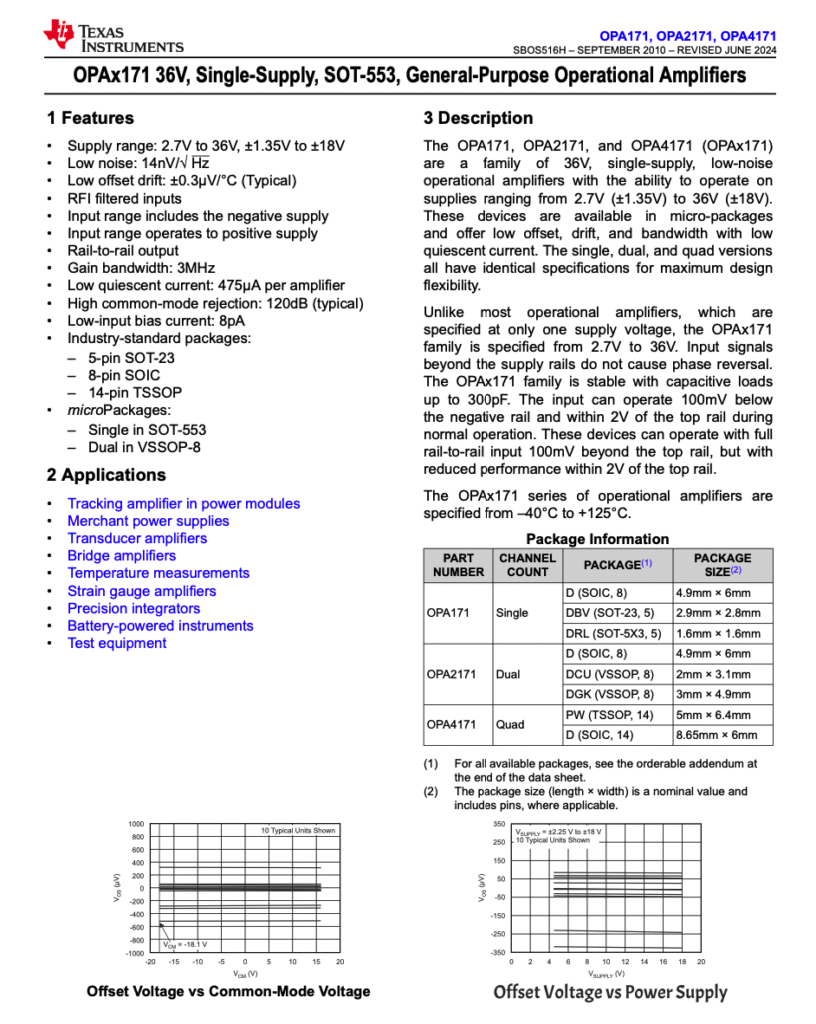

- Power supply range: 2.7V ~ 36V wide range, compatible with 12V or 24V rail input

- Input bias current: typical value is only 8pA, suitable for small signal sampling

- Input offset voltage: typical 0.25mV, with low full-temperature drift down to ±0.3μV/°C

- Gain Bandwidth Product (GBW): 3MHz, the bandwidth meets medium and high-speed control requirements

- Common Mode Rejection Ratio (CMRR): up to 120dB, effectively suppressing power supply noise

- Power consumption: 475μA per channel, low power consumption facilitates high-density layout

- Amplification of pre-stage current signals in three-phase sampling

- Post-stage op-amp matching with isolation amplifiers or ADC inputs

- Suppression of common-mode interference and improvement of system anti-interference capability

- Low power consumption meets the requirements of high efficiency and low thermal design

AMC1200B: The Perfect Integration of Precision and Isolation

- Input Range: ±250mV differential, compatible with shunt resistors

- Fixed Gain: 8x, with a ±0.5% gain error

- Nonlinearity Error: ≤0.075% (@5V supply)

- Isolation Voltage: 4250Vpeak, compliant with the UL1577 standard

- Bandwidth: Minimum 60kHz, suitable for PFC frequency bands

- Common-Mode Transient Immunity (CMTI): ≥10kV/μs, effectively shielding surge interference

- Isolated current sampling, ensuring safe decoupling between the MCU and the high-voltage side

- Differential output directly connected to ADC, improving sampling stability

- Bandwidth covering typical operating conditions from 50/60Hz to tens of kHz

- Compatible with industrial temperature range: -40°C ~ +105°C

Engineering Practice: Precision and Protection Logic of the Sampling Circuit

| Link Position | Function |

|---|---|

| Shunt resistor | Converts current to voltage, serving as the signal source |

| OPA2171 | Amplifies small signals to improve Signal-to-Noise Ratio (SNR) |

| AMC1200B | Provides high-voltage isolation + high-precision differential output |

| MCU ADC | Digitizes the signal and determines whether overcurrent or offset occurs |

- Control error: The PFC inductor cannot be adjusted correctly.

- Protection delay: Overcurrent signals are not recognized, which may burn the MOSFET (Metal-Oxide-Semiconductor Field-Effect Transistor).

- EMC issue: High common-mode interference couples into the main control ground.

Suggestions for Analog Chip Selection

| Comparison Dimension | OPA2171 | Alternative Recommendations |

|---|---|---|

| Performance Stability | ✅ Low temperature drift | OPA192 (lower drift) |

| Noise Requirement | ✅ Low-frequency stability | OPA2333 (lower noise) |

| Package Option | Multiple options (VSSOP/SOIC) | – |

| Comparison Dimension | AMC1200B | Alternative Recommendations |

|---|---|---|

| Isolation Level | ✅ 4250V | AMC3302 (higher CMTI) |

| Bandwidth | ✅ PFC-compatible | AMC1301 (wider bandwidth) |

Written in the End