The “explosion” or “zhaji”of EV chargerg power modules (usually referring to severe damage to power modules, such as cracking, burning, short circuits, etc.) is a serious fault that may be caused by various factors acting alone or together. Understanding the causes and conducting targeted maintenance are key to prevention.

I. Main Causes of “Explosion” (Zhaji) in EV Charger Power Module

- Overvoltage Surge

- Power Grid Surge: Transient high-voltage impacts caused by lightning induction, start/stop of large-scale equipment, power grid switching, etc., which exceed the voltage withstand limit of the module.

- Operational Overvoltage: Peak voltages (e.g., turn-off overvoltage) generated by switching devices inside the module (such as IGBTs and MOSFETs) during the switching process. If the absorption circuit (e.g., RC absorption, RCD clamping) fails or is improperly designed, it may break down the devices.

- Load-Side Reverse Inrush: Abnormalities in the vehicle battery or BMS (Battery Management System) cause energy to flow back into the charging module, resulting in overvoltage.

- Overcurrent/Overload

- Output Short Circuit: Short circuits occurring in the charging gun, cable, vehicle interface, or inside the battery, generating an extremely large current that far exceeds the module’s design capacity.

- Overload Operation: Prolonged operation beyond the module’s rated power leads to accumulated overheating of components, eventually causing thermal breakdown.

- Startup Inrush Current: In some cases, the current is excessively high at the moment the module starts or the load is connected.

- Overheating

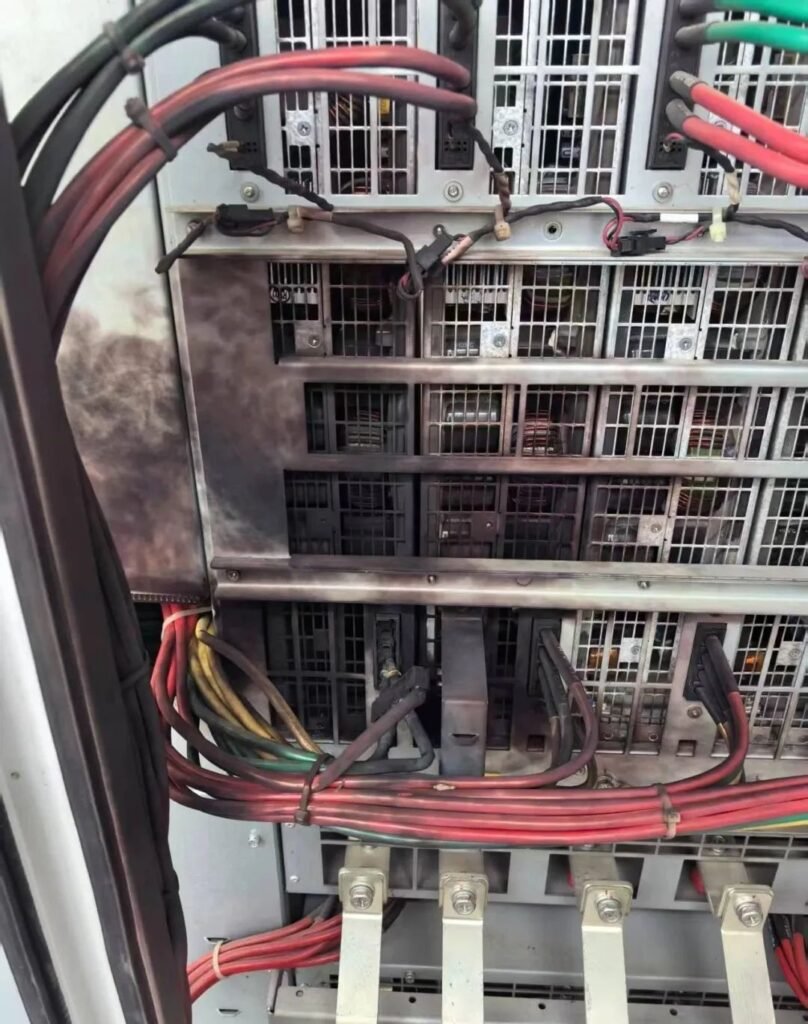

- Fan Malfunction: Fan stalling or insufficient rotational speed.

- Severe Dust Accumulation on Heat Sinks: Blocking the air duct.

- Aging and Drying of Thermal Grease: Deterioration of thermal conductivity.

- Excessively High Ambient Temperature: For example, poor ventilation in the charger cabinet or exposure to intense sunlight.

- Poor Heat Dissipation: This is one of the most common causes.

- Overload Operation: Sustained high-power output generates a large amount of heat.

- Poor Internal Contact: Issues such as loose connectors or cold solder joints increase local resistance, producing additional Joule heat.

4. Component Failure

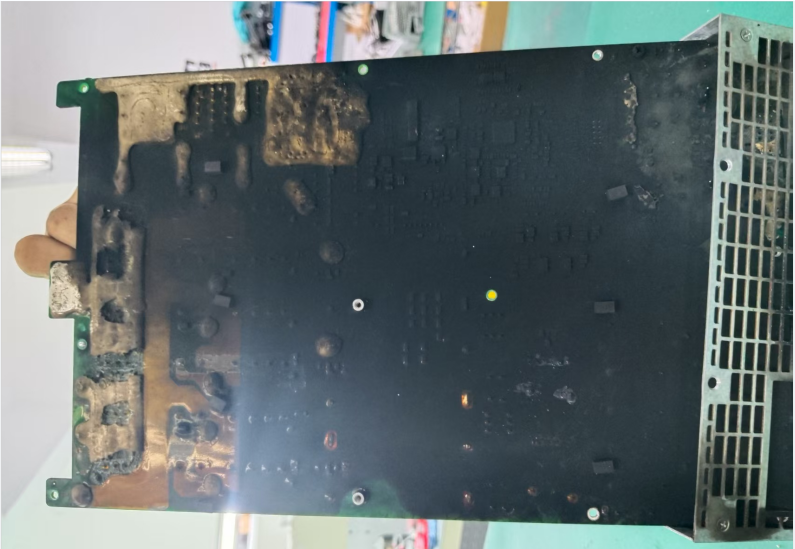

- Power Device Failure: Core power devices such as IGBTs, MOSFETs, and diodes may suddenly break down and short-circuit even under normal operating conditions if they have inherent defects, are aged, or have reached the end of their service life.

- Drive Circuit Failure: Damage to the drive chip, abnormalities in drive resistors/capacitors, etc., lead to abnormal drive signals for power devices (e.g., direct conduction of upper and lower switches), causing short-circuit and severe damage (“explosion”).

- Absorption/Protection Circuit Failure: As mentioned earlier, burnout of resistors, breakdown or failure of capacitors in RC or RCD absorption circuits result in the loss of protective function.

- Electrolytic Capacitor Failure: Bulging, liquid leakage, capacity reduction, or ESR (Equivalent Series Resistance) increase of input/output filter capacitors or DC-Link capacitors affects the stability of the bus voltage and may even cause short circuits.

- Sensor Failure: Malfunctions of current, voltage, or temperature sensors lead to misjudgment by the control loop, failing to provide proper protection.

5. Design/Manufacturing Defects

- Insufficient Electrical Clearance/Creepage Distance: Prone to arcing and short circuits in humid or dusty environments.

- Inadequate Component Selection Margin: Device parameters are too close to the limit values, making them vulnerable to damage when operating conditions fluctuate.

- Unreasonable Heat Dissipation Design: Insufficient thermal simulation results in heat dissipation capacity failing to meet actual requirements.

- PCB Design Defects: Issues such as overly thin traces, insufficient via current-carrying capacity, or unreasonable layout cause local overheating or interference.

- Production Process Problems: Cold soldering, solder bridging, foreign matter residue, etc.

6. Environmental Factors

- Humidity/Condensation: Reduces insulation performance, leading to discharge, short circuits, and corrosion.

- Dust, Salt Spray, Chemical Corrosion: Blocks air ducts, corrodes components and circuit boards, and degrades insulation.

- Vibration: Long-term vibration causes loose connectors, cracked solder joints, and fatigue fracture of component pins.

7. Software/Control Logic Failures

- Control Algorithm Bugs: Cause abnormal switching operations.

- Protection Logic Failure or Improper Threshold Setting: Fail to respond promptly to overvoltage, overcurrent, or overheating.